- Details

- Category: Uncategorised

TIPS:

1: Make sure to cut on the "dull" surface. When cutting heat transfer material, you will need to always cut the "dull" surface side of the material. Never cut on the "shiny" side.The "shiny" side is actually the built-in transfer tape.

The "dull" side is the heat-activated adhesive side.

Secret to the home iron...

1:Make sure it's hot enough.

2:Make sure your surface is HARD... can use a cutting board on a table.

3:Make sure you can apply pressure to the iron. use YOUR body weight.

4:Make sure to use a sheet of parchment paper or pillowcase,teflon sheet under your iron so that it doesn't drag. Iron on a hard surface.

5:Dry Heat is also important. You can check its adherence by lifting up a little corner of the carrier sheet. If not sticking, do again. Does take a little longer with regular iron.

1:Cut in reverse weed, cut on the "dull" surface.

2:45°/60° blade, our vinyl thickness is 110 Microns ,more thicker than

Siser vinyl (90 Microns ), so set the knife a little deeper.

3:set the speed faster (at 50-75) for a large design, and at 25 definitely for a small one.

Preheat garment for 2-3 seconds

PVC HTV Temperature: 302°F-320°F (150°C-160°C),

Glitter HTV : 320°F-338°F (160°C-170°C)

Pressure: Firm

Time: 8-12 seconds

Peel COOL,wait about 15 seconds

For best performance, cover and reheat for 2-3 seconds.

2: PVC vinyl transfer vs PU vinyl transfer

- These PU products tend to be thinner and more stretchable so they feel like part of the garment. This soft "hand" is what makes them so perfect for apparel graphics.

- PU transfer films are safe for young children who may mouth the garment and its applique.

- This soft "hand" is what makes them so perfect for apparel graphics.

PVC T-shirt films are generally thicker and less expensive.

FOR PVC VINYL , It's not sticking on the clear backing ( the "shiny" side), when you remove the vinyl you don't want to use.Be careful : When you go to peal off the backing everything comes right off. The design does not stay put. If you happen to peal off the RIGHT design, you can use a little Clear Office Glue, stick back them on the "shiny" side.

PU VINYL is sticking on the clear backing,

because there are glue on the the clear backing.

So the PVC is suited for larger images like numbers and such.

For SMAILL fine detail and a softer hand use the PU.

For Example:

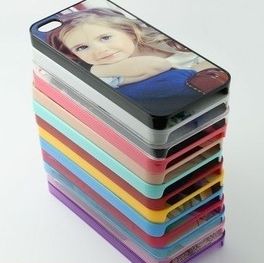

THESE KIND PICTURE, YOU SHOULD USE PU

|

|

larger images like numbers and LETTER, YOU CAN USE PVC vinyl transfer

3:For best results, apply ample pressure while using your iron's cotton setting.

3:Always remember to mirror. When cutting heat transfer material, it is vital to always horizontally mirror your images (by right-clicking and selcting to mirror horizontally). That way, your text and asymmetrical images will come out correctly when laid onto your desired surface and not be backwards.

5:Highly textured fabrics or loosely knit fabrics are not ideal for use with heat transfer material.

6:Once your project is finished and the transfer surface has been removed leaving your project, you may wish to again iron (directly for flocked and with a thin pressing cloth for smooth) without the additional plastic surface in order to provide additional heated pressure

7:After wearing (if a garment of any sort), you will want to wash the garment inside-out.

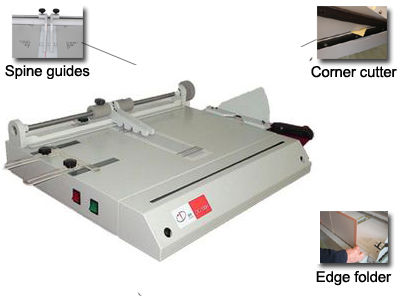

DOWNLOAD MANUAL HERE: