Silk screen printing business start up packages

- Details

- Category: Screen Printing

- Published on Friday, 16 March 2012 13:17

- Written by shichang ding

- Hits: 4881

The silk screen printing business opportunity is great for stay at home moms or for a person looking for a second income. Everyone owns a shirt, so why not make money from it using our press. Screen printing can be done on t-shirts, sweatshirts, mouse pads, stickers, binders, and much more.

Our goal is to help you profit in the screen printing business without a large investment (which is required by other companies).

You get real equipment, supplies (ink, emulsion, squeegees, etc.), and a Start kit that takes you through the silk-screen process step-by-step (assembly, burning the image on a silk-screen, printing the t-shirt, and more). Learn how to start up silkscreen printing business and make money.

Dingword offers you a series of silk screen printing business start up kits which can meed your different demand. From 1 color silk screen printing start up machine kit to 6 color silk screen printing start up machine kit, you can choose from different prices and various combines.

We have 5 Silk Screen Printing business start up Kits for you to choose from :

1: 1 Color 1 Station Screen Printing business start up Package

2: 4 Color 1 Station Screen Printing business start up Package

3: 4 Color 2 Station Screen Printing business start up Package

4: 4 Color 4 Station Screen Printing business start up Package

5: 6-color 6-station Screen Printing business start up Package

Silk screen printing theory

- Details

- Category: Screen Printing

- Published on Tuesday, 29 March 2011 15:06

- Hits: 4212

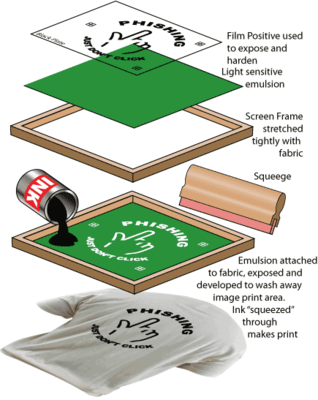

Method of printing based on stencilling. It can be used to print on most surfaces, including paper, plastic, fabric, and wood. A fine mesh (originally silk) is stretched across a wooden frame to form the screen. An impermeable stencil (either paper or a photosensitized coating) is applied to it, so that the ink passes through to the area beneath only where an image is required. The design can also be painted directly on to the screen with varnish. Once the stencil is attached, the screen is placed on top of fabric. Printing ink or dye is then drawn across, transferring the design to the fabric. A series of screens can be used to add successive layers of colour to the design. The process was developed in the early 20th century for commercial use and adopted by many artists from the 1930s onwards, most notably US artist Andy Warhol.

The Trend of Screen Printing Market

- Details

- Category: Screen Printing

- Published on Tuesday, 26 April 2011 13:31

- Hits: 5031

By Yuji Satoh,Screen Printing Research Center of NBC Inc

1. Contents

1) Analyze the screen printing market of Japan, Europe and America, and briefly explain the global market trends of screen printing.

2) With the change of market, the other technologies of mass production are developing and growing day by day. Specific explanations are given to the advantages and benefits of screen printing compared with the other technologies.

3) The market change raises higher requirements on screen printing in high precision and high refinement. Explanations on necessary functions are given today.

2. Market Trends of Screen Printing in Japan

1) The Japanese enterprises with mass production of PCB, CD and printing continue expanding to Asian countries, and the demands of mass production in Japan are declining.

2) As for image, the electronic digital printing as the other technologies of mass production are growing and developing day by day. However, because of different production quantity in each batch, the trend of autonomous administration with screen printing is being enhanced, and there will be no great demand increment judging from environment.

3) In Japan, the market demands of electronic component related products are likely to be enlarged. The specific items include LTCC, MLCC, FPD, solar battery, RFID, and COF, etc.

※ With the refinement development of these items, the demands on high precision and high refinement of screen printing will continue increasing.

3. Market Trends of Screen Printing in Europe and America……key words are “environment” and “electronic components of automobile”

1) In modern world, the environment issue is paid more and more attention. In such market situation, solar battery as one of future energy is placed much expectation. So far, Japan has been surpassing all the others in the production of solar battery. In future, the world output will continue increasing, especially when the European and American countries make greater plans in the production of solar battery. The technologies of screen printing will be extensively used and the demands will increase greatly especially in the production of silicon solar battery.

2) The proportion of body devices of each automobile is declining year by year; in contrast, that of electronic components is increasing gradually. It is reported that 70 million automobiles are manufactured in the world per year, and 20-30 thousand electronic components are placed on each automobiles. In future, with the development of high performance and environment friendly trend of automobiles, the electronic components on the body of automobile will be more and more. These electronic components, including HIC, MLCC, inductor and coil, are all the programs greatly requiring the technologies of screen printing, and the demands are inevitable to be enlarged.

4. Advantages of Screen Printing

1) Comparison between screen printing and intaglio printing. As far as the procedure of forming of passive film on the surface of silicon is concerned, 8 procedures are needed for intaglio printing, while only 2 procedures are needed for screen printing. The procedures are simplified greatly. However, because solder paste which is inconvenient for printing is used, and high precision printing dimensions are required, high precision screen is needed.

2) Comparison between screen printing and offset printing. When the procedures of necessary additive painting on the liquid crystal panel in the same production condition are compared, the producing capacity of screen printing is 4 times of that of offset printing, thus greatly reduces the production cost. The problem with screen printing is to avoid the damage to the alignment film. If this problem can be solved, the market demands of screen printing will increase greatly with the development of the markets of automobile navigation, auto phone and LCD-TV.

5. Screen for Precise Printing

With the change of market, high precision and high performance gradually become the requirements on screen printing. With the high performance development of the products and the increase of components, the high refinement degree of wiring is higher and higher. In addition, to give full play to all the functions, various solder pastes are used, including many varieties which are not suitable for screen printing or are hard to be printed. This problem needs research and solution. In future, the trend of multi-layer will be increasingly obvious with the multi-layered film substrate represented by HIC; therefore, high precision printing will become more and more important. The screen with high strength, high elasticity and low degree of stretch is necessary for these demands.

6. High Strength • High Elasticity

During the course of high precision and high performance, there is an example of screen meeting the requirements.

By comparing the strength feature of polyester screen, stainless steel screen and V-screen made of PAR, it is easy to find that V-screen shows outstanding performance in both strength and elasticity, with over twice strength of stainless screen and much higher elasticity than stainless steel screen. In future, for the increasingly enlarged precision printing, such materials with high strength and elasticity as V-screen will realize the dimension precision of high-resolution printing.

In tune with the market change, thorough discussion and research on the materials of screen printing --- screen, screen frame, adhesives, solder pastes, printing machine and printing condition will play important roles in the future development of the screen printing market.

The advantage of an aluminum screen printing frame

- Details

- Category: Screen Printing

- Published on Wednesday, 16 March 2011 02:22

- Hits: 3996

The advantage of an aluminum screen printing frame is the durability and longevity it retains. Unlike wood silk screen printing frames, when exposing frames to water in a dip tank or washout sink aluminum frames will not warp. This will insure a flat frame through thousands of prints to come. Aluminum frames can also be stretched and re-stretched many times. The mesh and glue are simply removed from the frame using a professional tool that doesnt damage the aluminum. Once cleaned, the frames can then be re-stretched which will give you the ability to use that frame for years of hard work in your shop.

Aluminum frames are also light weight which makes shipping less expensive and saves you money in the long run. If you're looking to maximize performance in your shop, aluminum frames are a great item to add to your screen printing equipment.

Tips on Buying Screen Printing Equipment

- Details

- Category: Screen Printing

- Published on Wednesday, 17 March 2010 12:32

- Hits: 5834

Tips on Buying Screen Printing Equipment

If you are looking to set up your own screen printing unit, whether for commercial purposes or personal use, you will need to invest in some basic screen printing equipment. A manual printing press, a flash curing unit and a conveyor dryer are some pieces of screen printing equipment that you will need.

Here are some tips on helping you select the best screen printing equipment for your use.

Selecting A Manual Printing Press

There are a wide variety of printing presses in the market. It can be pretty difficult to pick one. Keep in mind the following things when shopping for a manual printing press and you should be able to make a good choice.

- Buy a six-color or four-color press: Depending on your requirements look to buy a six-color or four-color press. If you are setting up a small unit for specific purposes only, then a four-color press should suffice. However, if you are looking to use the press for commercial uses, it will be better to spend a little extra and buy the six-color press to keep pace with competition.

- Ensure that the press is sturdy. Buying a really sturdy press can drive the cost a little higher but it will be worth it in the end. If the center arm that holds the shirtboard is not sturdy and bends or bows, the print quality will be compromised.

- Micro adjustment can really help speed things up and better the print quality. Not an essential requirement but very desirable.

- Look for a press that says "All Heads Down". This means that you have six printing heads over six printing stations and can have more than one person print at the same time. This will allow you to multiply your production many times over with just one press.

Selecting A Flash Curing

A flash curing unit is the same heater that is used in a conveyor dryer except it does not have the conveyor or tunnel. Since flash curing units use infrared rays that only cure the surface they touch and do not heat the air around it, a tunnel is not absolutely essential. The flash curing unit will work equally well without the tunnel.You can get a cure in just a few seconds with a flash curing unit and hence the name - flash or spot curing unit.

- Depending on the usage decide on the size of the heater. If you plan to use it only for a specific purpose and a specific size of prints then you can choose a smaller heater measuring 16" x 16". However, for commercial purposes something in the range of 24" x 24" is really required.

- Invest in a sturdy stand if you want to avoid tipping over the heater. Good large wheels on the stand are also a great idea because you are invariably moving the heater around.

- Get a heater with the automatic cycle feature. It will more than pay for itself by saving you curing time and a lot of trouble wondering whether the print has been cured or not.

- Some manufacturers promote a heat controller but most printers tend to run their units on full heat anyways. So pay for this only if you are sure you want to use it.

Selecting A Conveyor Dryer

If you are looking to print large quantities of t-shirts or merchandise with your screen printing unit, then a conveyor dryer is a must. A flash dryer can generally handle a few dozen t-shirts a week comfortably. But for greater quantities, you need to upgrade to a conveyor dryer.

- Decide on the conveyor size depending on your requirements. A 6' to 8' long dryer with a 24" conveyor can generally handle about 8-12 dozen shirt an hour. If you increase that to a 8' to 10' dryer with a 30" conveyor you can cure almost twice the number of shirts.

- Look for adjustable heater height so that by lowering the height you can get the ink to dry faster and yet accommodate taller products through the dryer when needed.

- Look for a dryer that is easy to maintain and find spare parts for. Some of the larger, fancier dryers are so fancy that it can take days to get them apart, fix the part and restart them. This can cost you good money. Try buying a dryer under warranty or sign up an annual maintenance contract.

- Forced air feature is good if you plan to print with air-dry inks used for towels and non-textiles.

Thus, you must decide on the output you expect from your screen printing equipment to help you buy the right equipment. Also, keep in mind your expansion plans when buying the unit so that you don't have to reinvest in expensive screen printing equipment too soon.Screen printing is an extremely affordable method of printing and hence very popular. However. sometimes because it is so economical people associate the low cost with low quality. That is not necessarily true. Screen printing can give fantastic results. However it is important to go to a screen printing expert who knows what he is doing. Here are some tips for screen printing that you can use on DIY projects. These tips will also come handy when you need to evaluate potential screen printers for your screen printing needs.